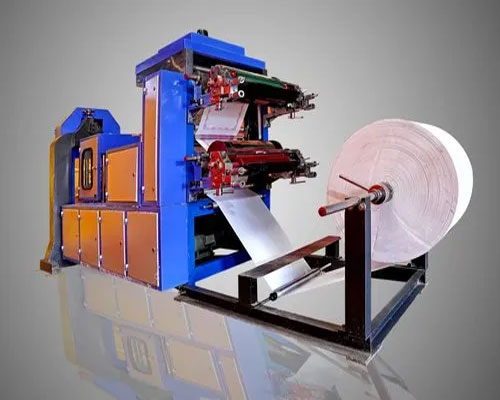

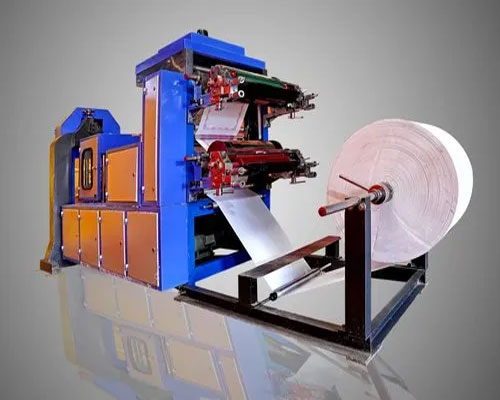

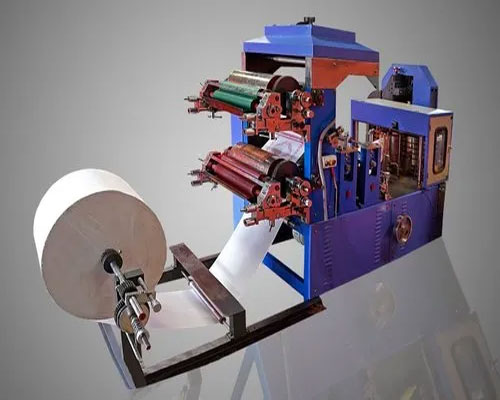

Tissue Paper Making Machine

Welcome to Alpha Napkin Machines, a premier tissue paper making machine manufacturer in Arunachal Pradesh. At Alpha Napkin Machines, we are committed to delivering high-quality and innovative manufacturing solutions tailored to meet the unique needs of our clients. Under the expert guidance of Mr. Vipin Kumar, we have established ourselves as a leading name in the industry, known for our dedication to excellence and customer satisfaction.

Our advanced tissue paper making machines are designed to enhance productivity, efficiency, and reliability. We use state-of-the-art technology and high-grade materials to ensure that each machine meets the highest standards of performance. Whether you are looking to start a small-scale operation or expand your existing production line, Alpha Napkin Machines offers customized solutions to help you achieve your business goals.

Boost Your Production Efficiency

Upgrade to our Tissue Paper Making Machine and see a significant increase in your production efficiency. Reduce downtime and maximize output with our state-of-the-art technology.

Explore Our Automatic Machines NowType of Tissue Paper Making Machine

40x40 Automatic Tissue/ Napkin Making Machines

| Automation Grade | FULLY-AUTOMATIC |

| Phase | Single Phase/Three Phase |

| Driven Type | Electric |

| Capacity | 200000 per Shift |

| Brand | ALPHA |

| Power Consumption | AC 220 volts 50 Hz. 2.2 kw |

| Automatic Grade | Automatic |

| Brand/Make | ALPHA |

| Voltage | 220/380 V |

| Power | 3.7 kW |

| Weight | 2500 kg |

Read more..

Single Embossing Without Printing Tissue/ Napkin Machine

| Model Name/Number | AP30C2E2P |

| Driven Type | Electric |

| Machine Type | Bandsaw |

| Capacity | 200000-250000 Per Shift |

| Brand | ALPHA |

| Automatic Grade | Automatic |

| Brand/Make | ALPHA |

| Automation Grade | Automatic |

| Warranty | 1 YEAR |

| I Deal In | New Only |

| Voltage | 220 V |

| Power (W) | 2.2 kW |

| Dimension | 6000x2600x1600 mm |

Read more..

Double Printing Double Embossing Tissue Making Machine

| Brand | ALPHA |

| Driven Type | Electric |

| Capacity | 200000 per Shift |

| Napkin Type | 4 Fold |

| Machine Type | Bandsaw |

| Automatic Grade | Automatic |

| Brand/Make | ALPHA |

| Speed | 200000-250000/Per Shift/Per 8 Hour |

| Warranty | 1 year |

| Automation Grade | Automatic |

| I Deal In | New Only |

| Power source | Electric |

| Voltage | 380 V |

| Type | TISSUE MAKING MACHINES |

Read more..

Multisizes Tissue Making Machine

| Minimum Order Quantity | 1 Piece |

| Model Name/Number | AP30C2E2P |

| Brand | ROYAL |

| Capacity | 80000-90000 Per Shift |

| Machine Type | Automatic |

| Dimension | 4.5 Feet X 16Feet |

| Voltage | 220V |

| Napkin Type | 4Fold |

| Driven Type | Electric |

| Automation Grade | Automatic |

Read more..

Key Features of Our Tissue Paper Making Machines

High Efficiency

Our machines are designed to maximize production efficiency. With advanced automation and precise control systems, they ensure high-speed operation and minimal downtime, boosting overall productivity.

User-Friendly Operation

Ease of use is a key feature of our tissue paper making machines. They come with intuitive controls and user-friendly interfaces, making it easy for operators to manage and maintain the equipment.

Energy Efficiency

Energy efficiency is a crucial consideration in modern manufacturing. Our machines are engineered to consume less power while maintaining optimal performance, helping businesses reduce their energy costs and environmental footprint.

Durability and Reliability

Built to last, our tissue paper making machines are constructed from durable materials that withstand the rigors of continuous use. Their robust design ensures long-term reliability and minimal maintenance requirements.

Why Choose Alpha Napkin Machines?

When it comes to investing in paper napkin making machinery, choosing the right partner is crucial. Alpha Napkin Machines stands out as the preferred choice for businesses across India and beyond.

- Quality Craftsmanship: Our machines are built with precision and using top-quality components to ensure durability and optimal performance.

- Advanced Technology: We incorporate the latest technology into our machines to enhance productivity and reduce operational costs.

- Customization Options: We understand the unique requirements of our clients. Our machines can be customized to meet specific production needs.

- Excellent Customer Support: Our dedicated team provides comprehensive support and after-sales service to ensure smooth operations.

- Competitive Pricing: We offer competitive pricing without compromising on quality.

Faq's

-

What are the primary components of a tissue paper making machine?

A tissue paper making machine typically consists of a paper roll stand, unwinding unit, tissue paper forming section, embossing unit, folding unit, cutting unit, and rewinding unit. These components work together to transform pulp into finished tissue paper products.

-

What types of tissue paper can be produced on these machines?

Tissue paper making machines can produce a wide range of products, including facial tissues, toilet paper, paper towels, napkins, and kitchen towels. The specific product depends on the machine configuration and the desired end product.

-

What is the average production capacity of a tissue paper making machine?

The production capacity varies significantly depending on the machine size, model, and the type of tissue paper being produced. Smaller machines may produce a few tons per day, while larger industrial machines can produce tens of tons per day.

-

What level of technical expertise is required to operate a tissue paper making machine?

While basic machine operation knowledge is essential, most modern machines are equipped with user-friendly interfaces. However, experienced operators can optimize production and troubleshoot issues effectively.

-

How often does a tissue paper making machine require maintenance?

Regular maintenance is crucial for optimal performance and longevity. Preventive maintenance schedules typically involve daily, weekly, and monthly checks, including cleaning, lubrication, and part inspections.

-

What are the common maintenance issues with tissue paper making machines?

Common maintenance issues include paper jams, blade wear, roller alignment problems, and electrical malfunctions. Proper training and regular inspections can help minimize downtime.